Can you weld structural steel

Flux recovery systems are available to dispense and recover welding flux. Seam Welder Hydraulic Power Unit (and Electric Controls) are used to drive the conveyors that enter and exit the Seam Welder.

The WS-72 is equipped with a Lincoln Power Wave AC/DC helder and Max-Sa controls. The WS-72 is equipped with unique magnets that pull web plates to copper back-up bars. The copper back up bar is made with a small flux groove. It is then fixed to an aluminum water-cooled subbar.

Each section can carry approximately 4,000 pounds of load. To reduce friction between the turning beam and the slower moving beam at the welder's entrance, conveyor speeds can be synchronized with the input speed of the welder.

Flux recovery systems are available to dispense and recover welding flux. Seam Welder Hydraulic Power Unit (and Electric Controls) are used to drive the conveyors that enter and exit the Seam Welder.

Gulf States Saw & Machinery Co has a progressive approach for solving the unique challenges that inevitably occur in our industry. Our goal is to provide efficient design, fabrication and timely shipment of custom equipment.

It will roll in one direction. Weld the side fuse so that the head is in the right place and the flanges on the center web. For a more secure weld onto your web, the flanges will be double-joined in most cases.

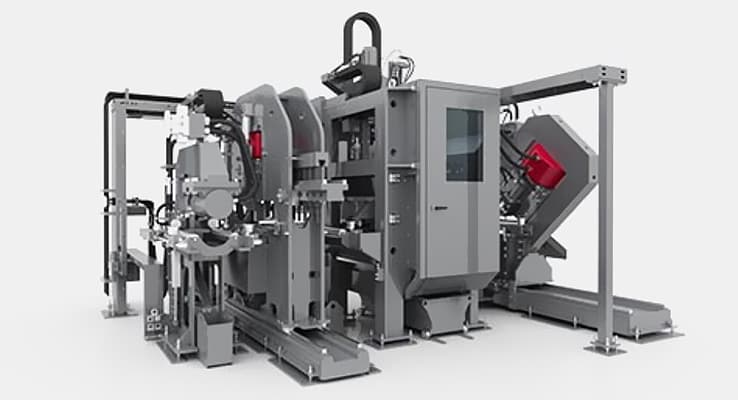

FRANKLIN MODEL PTW72 - A complete Automatic submerged twin arc welding system. It is capable of fixing and welding three-piece built up beams, consisting of a Web and two flanges. The PTW-72's web capacity is 72 inches. Flange capacities are 20" wide x 1/4" thick. A PTW72 complete fabricating cell can measure up to 300 ft. The system includes a web loading gantry as well as a web seam station and a tack unit unit.

Beam Layout Welding has easily accessible diagnostics indicators and message display. Custom graphics include electrical and hydraulic diagrams, and functional and functional diagrams. You can input program information via touch screen, keyboard or touch screen.

A welded beam consists of three individual sections of steel – a web, a top flange and a bottom flange. These segments are merged together with deep fillet welds to create an incredibly robust building material.