What is Ismc

Gulf States Saw & Machine Company provides modular Fusion Arc welding machines, in-house training classes and an extensive inventory of consumables. Certified welding and application engineers teach training classes.

The Gulf States Saw & Machine Company's Service Department holds the company together. It is the only one in the entire south. The current department has nearly 30 employees, including 24 Field Service Engineers strategically located throughout Capital's 12-state region. We offer an online Service Request Form to expedite your needs. In addition to several team members answering customer calls. These steps are why top-tier machine tool builders appreciate Capital's superior quality team and their pursuit of excellent service.

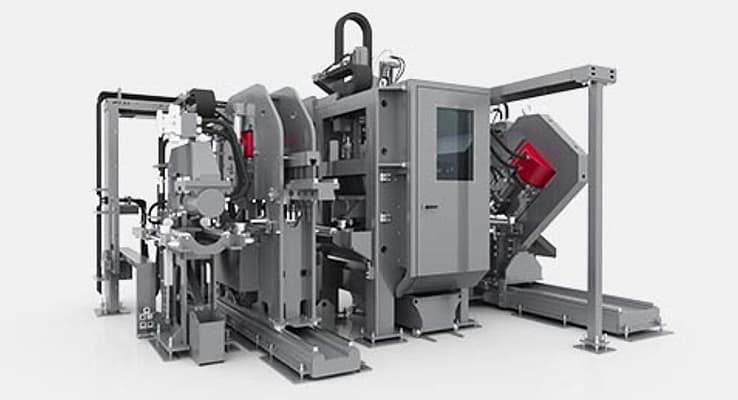

The two flanges will be placed on the conveyor section at opposite ends of web. The three pieces are positioned against a retractable stopping device and hydraulically clamped to their respective positions. The operator manually tack-welds them together. The clamps are released and the tack-welded beam can be sent to the welder. After setting up the clamp positions on the first beam, an operator controls material movement via the control panel. This is the same procedure for all subsequent beams.

Gulf States Saw & Machine Company provides modular Fusion Arc welding machines, in-house training classes and an extensive inventory of consumables. Certified welding and application engineers teach training classes.

Gulf States Saw & Machine Company�s Service Department is what keeps the company together. There is no other department like it in the south. The service department is currently composed of close to 30 people, with 24 Field Service Engineers strategically placed throughout Capital's 12-state regions. To help you expedite any service requests, we offer an online Service Request form. We have multiple staff members who answer customer calls. These are just a few of the reasons why Capital's quality team is regarded as the best in the industry and they strive for excellence in service delivery.

Welding or bolting are the most common methods of achieving this. The connection would be made from the underside of each flange or web. You could join them to improve or increase the strength of the support, or for it be possible to cover more components.

A typical Beam Layout welding system has 18 conveyor segments. Six of the sections are motorized, and drive the rollers with sprockets. Ten are motorized, and connected by chains to adjoining motorized sections. Two are inactive.

This allows you to produce custom beams with minimal delay for changing beam shapes or sizes. Beam Layout Welding allows you to increase your productivity on both straight beams as well as tapered beams. The system automatically welds the beam's two flanges together at once. This gives you the penetration you need up to 1/2" web and 1 1/2" flange in one operation. The PHI system produces an inter-flange fillet. Welds meet all construction codes and are uniform.

A welded beam consists of three individual sections of steel – a web, a top flange and a bottom flange. These segments are merged together with deep fillet welds to create an incredibly robust building material.