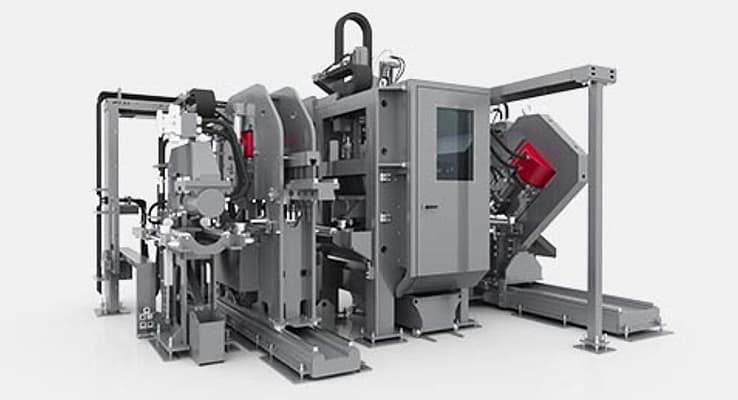

Beam Layout Welding For Beginners

Welding arm, which is the main part of welding work, can move horizontally along cross beam, together with tool carriage. Also, it can move up or down using the directional wheels on the tool carriage. It is mounted under the welding beam. Seam tracking device has the function of automatic track, which can maintain a suitable distance between welding gun & welding seam. Also, it has an auto compensation function for Hbeam deformation.