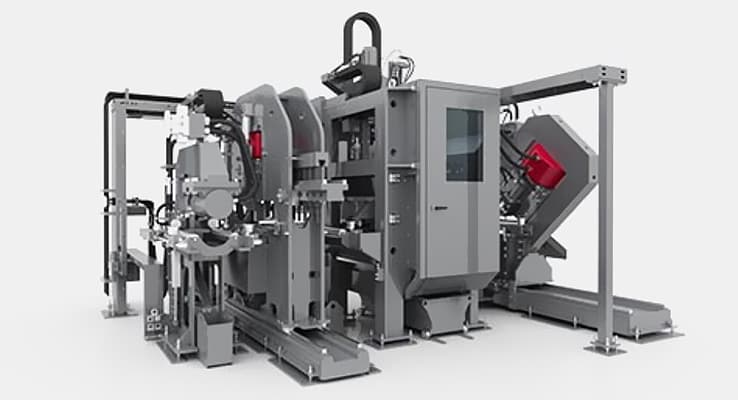

Large Volume Production

Our specialty is robotic welding and other Industrial applications for Robotics, such as Machine Tending or Material Handling. Capital Robotics' headquarters is located in Atlanta, but we also have a Dallas office that maintains systems and provides training to customers. Capital Robotics has always increased its technical staff, including application engineers, welders, and service engineers.

.jpg)