Why do welders drink milk

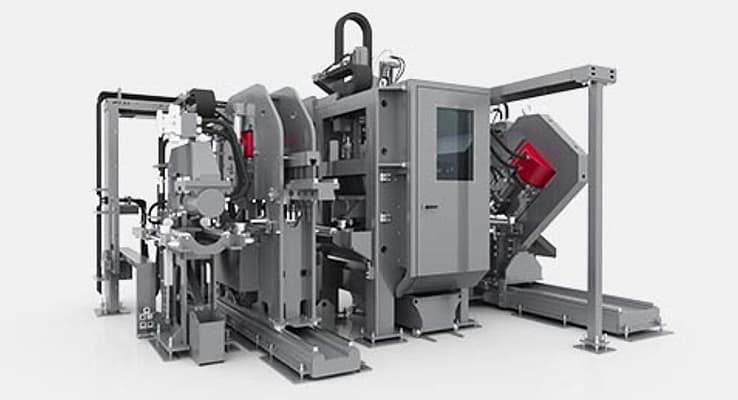

It is fitted with a solid underneath that holds the plate of metal while the weldheads go through it. Here are the flanges that make up the H beam. The web is made using a long piece from plate. It is loaded onto a conveyor belt-like welder roller along with the Flanges.