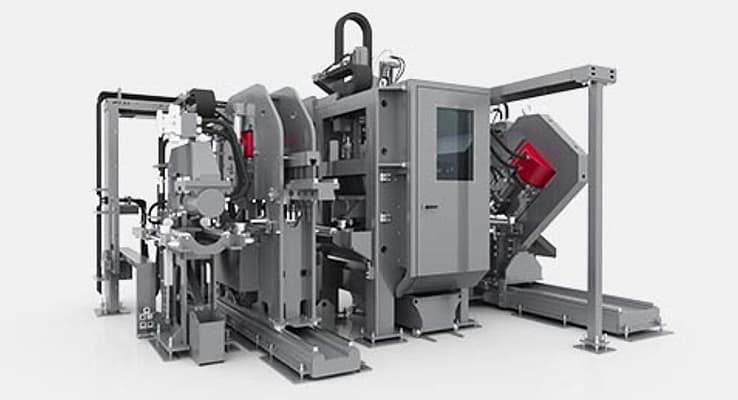

Laser Machine

An arc-guiding device fixes wire feeding device. This device connects wire feeder and wire reel together via wire feeding pipe. Wire reel supporter is for fixing wire reel. Place wire reel into the supporter prior to welding. Then, feed wire thrill through the feeding tube and connect it back to the machine.