Process

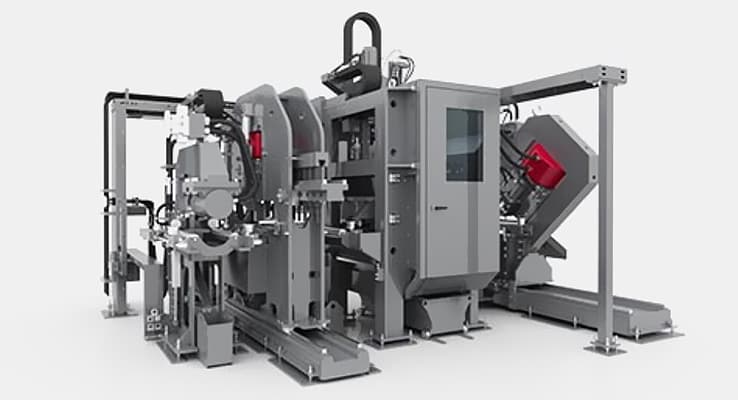

Thanks to years of experience in a wide array of industries and with a wide range of technology, we know how to help everyone from small job shops to large international brands utilize the latest equipment and technology. So no matter what type of machine you�re looking for, we can help design, specify, install and service just about any type of metal fabrication equipment.