Beam Layout Welding Kistler

Gulf States Saw & Machine Company offers modular Fusion Arc welder cells, in-house classes, and an abundance of consumables. The instructors of training classes are certified welders and application engineers.

.jpg)

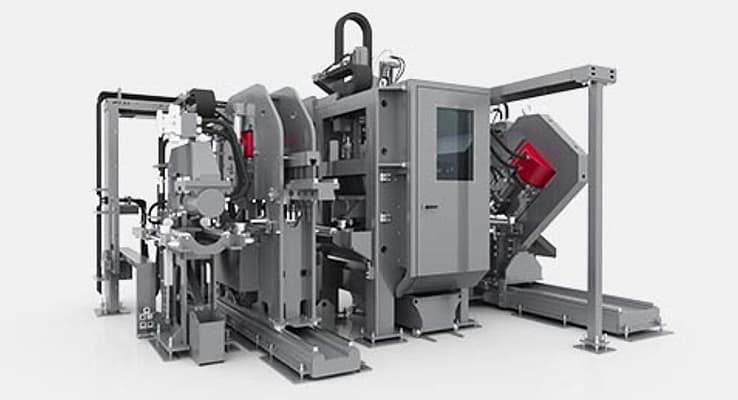

Beam layout welding is not just manual. An H beam fabrication line, or machine, can work on multiple H beams simultaneously. This flat-laid machine is used to feed long, uncut plates. The machine then handles welding each plate to achieve the desired design.

The Beam Layout Welding machine is fully customizable and is designed to join heavy-duty structural steel box sections. It is well-suited for civil construction and oil and gas industries. The Beam Layout Welding is equipped with component clamping, rotation via the tailstock and headstock. Beam Layout Welding can be controlled using the linear axis Z, Y, and Z as well as laser seam tracking devices. It also includes a wire feeder system. The integrated control system and motor drives fully automate the machine.

Gulf States Saw & Machine Company offers modular Fusion Arc welder cells, in-house classes, and an abundance of consumables. The instructors of training classes are certified welders and application engineers.

.jpg)

Gulf States Saw & Machine Co., Inc. is the largest southeast saw blade shop and offers more than 50,000 products through our supply catalogue. As important as large sales is taking care of our customers 24/7, 365 days a year. Gulf States Saw & Machine Co., Inc. is a well-respected company in the metal fabrication machinery business.

Beam Layout Welding includes easily accessible diagnostics indicator, message display and custom graphics. This includes electrical and hydraulic schematics as well as functional diagrams. Programming input can be done via touch screen and keyboard.

Gulf States Saw & Machinery Co. are world leaders in the field of structural steel fabrication technology. Beam Layout Welding machines give steel fabricators an advantage in the steel sector and allow them to maximize tonnage capacity.

You can use them for many purposes, as they are designed to bend and compress at their top and be tensed at their bottom. These are some of the reasons I beams are popular. Other benefits include its flexible design.

A welded beam consists of three individual sections of steel – a web, a top flange and a bottom flange. These segments are merged together with deep fillet welds to create an incredibly robust building material.