Beam Layout Welding

There will always be H beam welding machines on the market, especially when you consider that there are more manufacturers! Gulf States Saw & Machinery Co is the only manufacturer you can trust. We have been in the industry over a decade and have had nothing but happy clients.

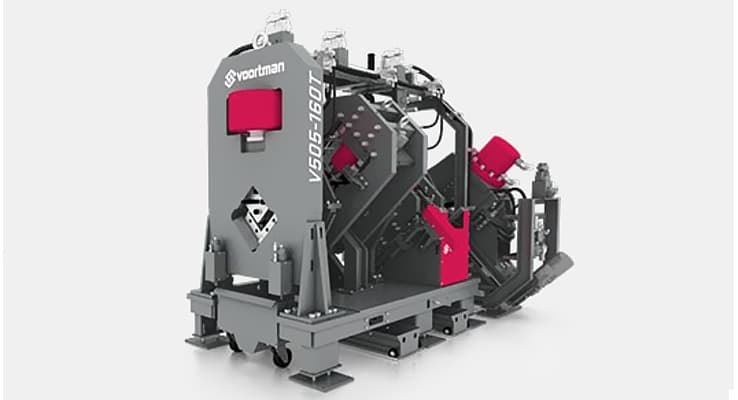

.jpg)