Beam Layout Welding Cost

The crane beam manufacturer can avail a special Beam Layout Welding heads design. The top flange in crane beams is a channel called a "C", with the short sides pointing inwards at the beam.

While they might look very similar at first glance, you will soon realize that they are quite different once you take into account all the details. Beam layout welding tends to be heavier and denser that I beams. This means that beam layout welding is more capable of absorbing and taking in more force.

This wire feeding device can connect wire feeder and reel together using wire feeding pipes. Wire reel supporter can be used to fix wire reel. Before welding, insert wire reel into supporter and then feed wire thrill through feeding tube.

The crane beam manufacturer can avail a special Beam Layout Welding heads design. The top flange in crane beams is a channel called a "C", with the short sides pointing inwards at the beam.

Gulf States Saw & Machinery Co. Beam-layout welding suppliers and manufacturers make different sizes. It will all depend on the requirements of the customer. It's best to fund an I-beam welding supplier and manufacturer. Not only will you receive the best prices, but you'll also be able help with installation.

Many people assume that H beams or I beams are the exact same. They aren't. While they might share the same structure, purpose and goals, they aren't one in the same. Here are some important differences to remember:

Each conveyor section has a load capacity of approximately 4,000 lbs. To minimize friction between the turning roller at the welder entry and the slower-moving beam at its entrance, conveyor speeds are synchronized to welder input speeds.

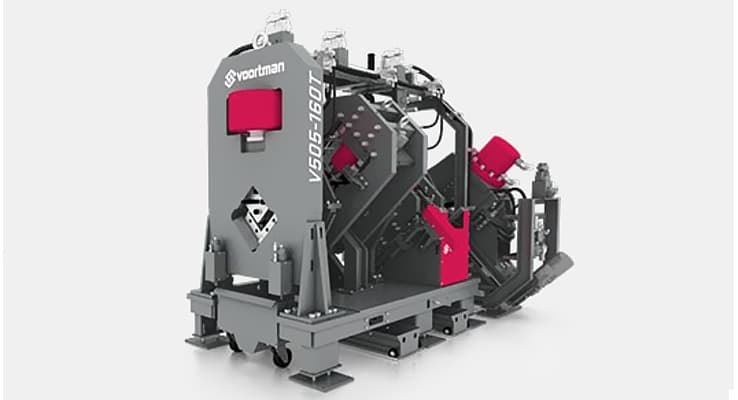

Beam Layout Welding program can be downloaded remotely over a network or connected PC. The software also comes with a 1-day data logger, which keeps track of the machine's operation. This option allows beams to be manufactured up to 84" instead of 72". All parts of the system have been modified to accommodate larger web sizes.

A welded beam consists of three individual sections of steel – a web, a top flange and a bottom flange. These segments are merged together with deep fillet welds to create an incredibly robust building material.