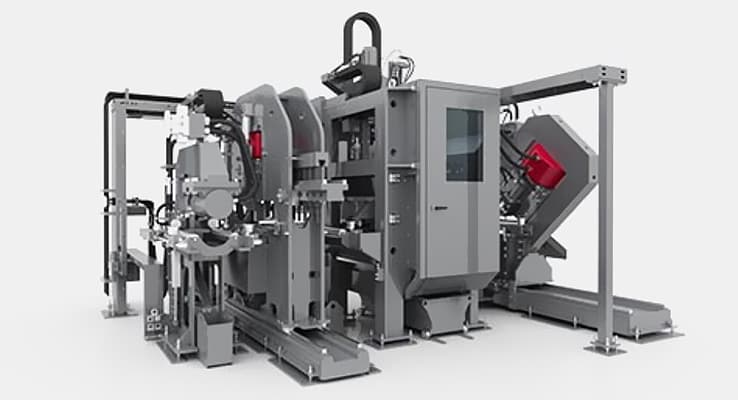

Beam Layout Welding Wall

Gulf States Saw & Machine Co. understands that not all fabricators will have the same needs. The nature and processes of different tasks can make it difficult to find the right machine for you. We have gathered only the most suitable structural fabrication machines to meet your needs. We have the right machine for you, no matter what your budget.