What is beam to beam connection in steel structure

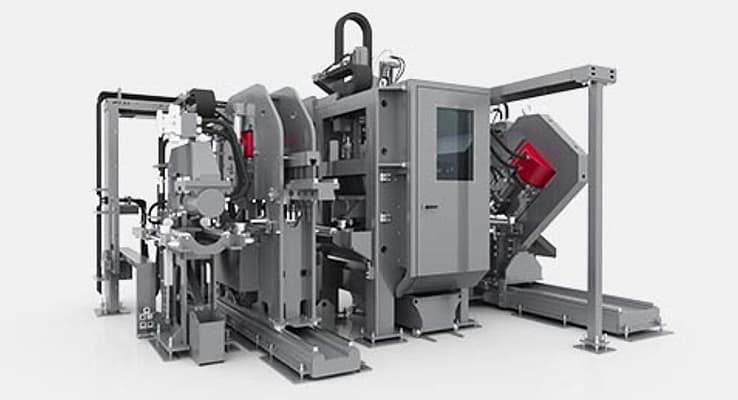

Beam Layout Welding can be downloaded remotely from any connected PC or network. It includes a one day data logger to record the machine's operations. This option allows for beams of maximum size 84" rather than the standard 72". All elements are modified to accommodate larger web size.